| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

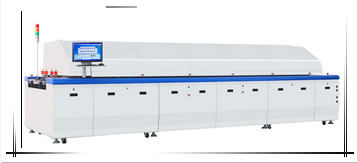

| Brand Name : | bez |

| Certification : | ce |

| Model Number : | 800e |

| Price : | 23800usd |

| Delivery Time : | 25days |

| Payment Terms : | t/t |

| Supply Ability : | 25sets/month |

> CE compliant

> Double clamshell hood for complete access

> Hinged, removable corner panels

> Lift-off front panels

> Heavy duty hood actuator with fail-safe clutch

> Convection heat and independent cool

> WithBuilt-in flux filter UPS support

> Gasket mounted blower motors

> Custom extrusion tunnel design

> Solid cast aluminum heater panels

> Custom conveyor extrusion with internal chain return

> Automatic chain oilers

> Precision linear cross-shafts

> Low air consumption

CS/HS/HD Series control software allows easy charting of real-time thermal data from up to three separate thermocouple inputs for precise profiling that matches solder paste manufacturers' critical lead-free reflow parameters. This allows users to set zone temperatures and conveyor speeds to the optimum settings that will produce the desired profile at the desired throughput. The thermocouples also allow monitoring of temperature sensitive components at specific locations on the PCB.

Longer heated zones length can obtain higher throughput and production efficiency.

Independent air velocity controlling by section can fulfill flexible processing adjustment,

therefore dealing with various & complicated lead free processing easily.

Dual-tracks conveyor is able to improve the production efficiency as well as power & cost.

Central support system to prevent the deformation of PCB board puzzle

Rail harden process to make it stability,with single pin-plate design conveyor chain

One block used for inner and motor new insulation,reduce loss of heat .Multi-layers and thicker thermal insulation to obtain the lower temp of oven surface effectively,

Siemens PLC with Modular as foreign famous brand components major parts ,obtain Reliable and durable guaranteed equipments

|  |

| Maximum Functionality, Ease-of-Use, and Trouble-Free Maintenance of CS-0602 ‘s DesignLockable access panels, air-cylinder-assisted hinged covers, and an automatic heating chamber hood lift, complement a well-thought-out and organized system architecture within a small footprint. | Automatic Hood-Lift Mechanism Allows Easy Access to Heating Chamber and Conveyor System for Cleaning and Maintenance.Photo shows the interior of the heating chamber with the hood in the raised position and bottom of the air diffuser panels of the upper heating zones center-support system [ Optional ] (avert board warpage from higher temperature.) |

|  |

| High Precision Stainless Steel Conveyor Mechanism Includes Automatic Lubrication Function The adjustable edge-pin type conveyor is constructed of high-quality stainless steel components and features a very stable, rugged design to maintain tight tolerances at the high temperatures associated with lead-free reflow. In conjunction with an automatic chain lubrication system (shown in this photo), Widened track structure PCB Production (double option) | The CS-0602 Includes a Built-In Flux Filter to Prevent Excess Residue from Entering Exhaust SystemA built-in flux filtering system removes large amounts of excess flux from exhausted air or nitrogen. The filter is accessible through the hinged panels on the rear of the system and is easily removed and cleaned with an alcohol-based cleaner. |

|  |

| High Precision Stainless Steel Conveyor Mechanism Includes Automatic Lubrication Function The adjustable edge-pin type conveyor is constructed of high-quality stainless steel components and features a very stable, rugged design to maintain tight tolerances at the high temperatures associated with lead-free reflow. In conjunction with an automatic chain lubrication system (shown in this photo), Widened track structure PCB Production (double option) | The CS-0602 Includes a Built-In Flux Filter to Prevent Excess Residue from Entering Exhaust SystemA built-in flux filtering system removes large amounts of excess flux from exhausted air or nitrogen. The filter is accessible through the hinged panels on the rear of the system and is easily removed and cleaned with an alcohol-based cleaner. |

|  |

| Automatic Startup and Shutdown Functions Provide Maximum Flexibility and Energy Saving PotentialTimed automatic startup and shutdown functions can be used to coordinate oven warm-up and cooldown times with breaks in production and transitions between up to three separate work shifts in each 24 hour period. These convenient scheduling tools will pay dividends through both energy conservation and production preparedness. | Full-Screen Temperature Profile RecordingThe CS Series control software allows easy charting of real-time thermal data from up to three separate thermocouple inputs for precise profiling that matches solder paste manufacturers' critical lead-free reflow parameters. This allows users to set zone temperatures and conveyor speeds to the optimum settings that will produce the desired profile at the desired throughput. The thermocouples also allow monitoring of temperature sensitive components at specific locations on the PCB. |

CS-Series Reflow Oven - General Specifications | ||||

Dimension(L*W*H)/Weight | 212" *54" *60" [5310x1353x1496mm] /Approx4840lbs[2200KG] | |||

Number Of Heating(Cooling ) Zones | Up8 / Bottom8-----2 (Cool Air Conversion) | |||

Length Of Heating Zones | 3121mm | |||

Exhaust Volume | 10 M3/ min x 2Exhausts | |||

Power Supply Required | 3 phase, 380V 50/60Hz (Optional: 3 phase, 220V 50/60Hz) | |||

Power For Warm Up / Consumption | 42KW/12KW | |||

Warming Time | Approx. 25/30 minute | |||

Power-off protection | UPS effectively prevent PCB being burnt out | |||

Transport system | mesh + chain-guide | |||

Transport Width | Mesh:19"(480mm)/rail: 2-16"(50-400mm) | |||

Conveyor Speed/Height | 16-71"/min (400-1800mm/min)35.4 ±0.8" (900mm ±20mm) | |||

Conveyor Direction | Left to Right | |||

Component Max. Height | 30mm upper, 25mm lower | |||

Temperature Control Accuracy | ±1° C | |||

Temperature Range (Tolerance) | Ambient -350° C/ ±2° C | |||

Double-Sided Board Processing | Yes | |||

PID+PLC+PC | Yes | |||

Windows Compatible PC | Yes | |||

Print Capability | Yes | |||

Data Logging & Event Recording | Yes | |||

CE Compliance | Yes | |||

Profiling / Thermocouple Channels | 3 | |||

Alarms/Language | Audible, Visual (Light Tower) and On-Screen Display/ (English) | |||

Nitrogen Atmosphere Compatible | Optional | |||

Auto Adjust Pin Conveyor | Optional | Internal Chilled Water Cooling | Optional | |

Double track rails | Optional | Powered Center Support | Optional | |

|